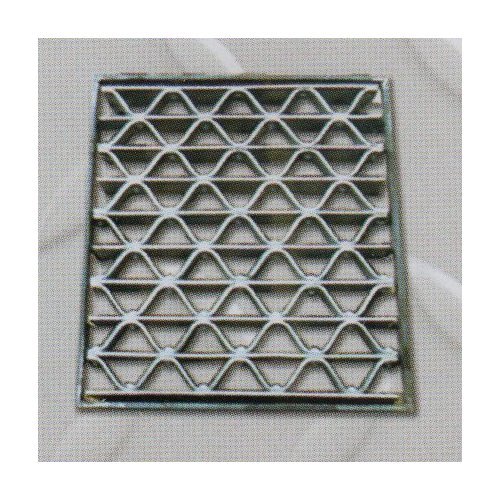

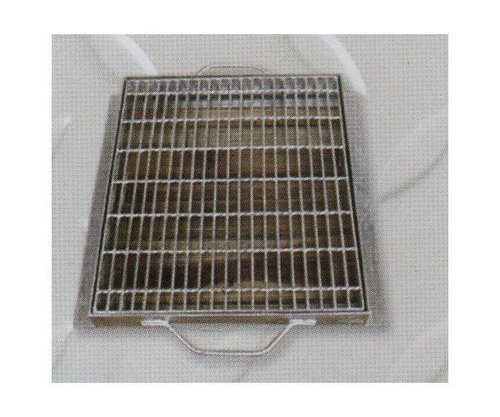

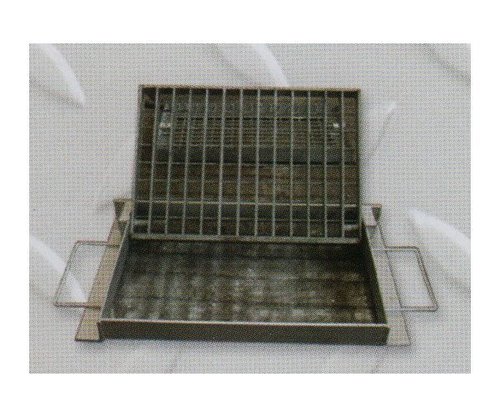

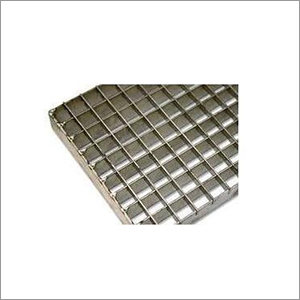

Aluminium Grating

MOQ : 200 Pieces

Aluminium Grating Specification

- Height

- 25 mm 100 mm

- Shape

- Rectangular/Custom

- Length

- 1000 mm 6000 mm

- Product Type

- Aluminium Grating

- Material

- High Grade Aluminium

- Application

- Industrial Flooring, Walkways, Platforms, Stair Treads, Drainage Covers

- Surface Treatment

- Anodized/Powder Coated

- Size

- Customizable as per client requirement

- Width

- 250 mm

- Manufacturing Process

- Pressure Locked / Welded

- Corrosion Resistance

- Excellent

- Color

- Silver (Natural Aluminium)

- Slip Resistance

- High

- Bar Pitch

- 40 mm

- Weight

- Approx. 5 kg/m²

- Cross Bar Pitch

- 100 mm

- Edge Type

- Plain or Serrated

- Maintenance

- Low

- Load Bearing Capacity

- Heavy Duty

- Fire Safety

- Non-Combustible

Aluminium Grating Trade Information

- Minimum Order Quantity

- 200 Pieces

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 15 Days

About Aluminium Grating

Aluminum Grating offered by us is commonly used as a drainage trench cover in municipal engineering and residential construction sites to drain water, keep the ground dry, and block garbage. It can be utilized as a pedestrian stair tread grating in commercial structures. It is lower in weight than stainless steel grating, making it easier to carry and install. Aluminum Grating is frequently utilized in commercial and industrial applications due to its outstanding corrosion resistance and lightweight characteristics. It has superior corrosion resistance than carbon steel grating.

Heavy Duty Aluminium Grating for Industrial Use

Designed for robust industrial settings, our aluminium grating stands out for its heavy load-bearing capability and high slip resistance. The combination of pressure-locked or welded manufacturing ensures structural reliability. This product suits flooring, platforms, walkways, and drainage covers, delivering safety and a long service life in areas demanding strength and corrosion resistance.

Customizable and Safe Flooring Solutions

Tailor your aluminium grating to specific requirements, with customizable width, height, length, and shape. Enhanced by a non-combustible, anodized or powder-coated surface, it provides low-maintenance, secure footing. Choose between plain or serrated edge types to maximize safety for your facilitys unique needs.

FAQs of Aluminium Grating:

Q: How is the aluminium grating manufactured and what processes are used?

A: Our aluminium gratings are fabricated using either pressure-locked or welded techniques. This ensures excellent structural integrity and durability, making them suitable for heavy-duty industrial use. These processes also allow for customization in size and shape according to client specifications.Q: What applications are best suited for this aluminium grating?

A: This grating is ideal for industrial flooring, walkways, platforms, stair treads, and drainage covers. Its robust load-bearing capacity, non-combustibility, and high slip resistance make it well-suited for environments that require secure and long-lasting access solutions.Q: When should I consider using serrated edge types?

A: Serrated edge grating is recommended for environments where additional slip resistance is necessary, such as in areas exposed to moisture, oils, or other slippery substances. The serrated profile significantly enhances safety underfoot for both workers and visitors.Q: Where can this aluminium grating be installed?

A: These gratings can be installed in a wide range of settings, including factories, plants, warehouses, refineries, and outdoor platforms. Their resistance to corrosion and fire makes them particularly appropriate for both indoor and outdoor environments exposed to harsh conditions.Q: What are the benefits of the anodized or powder-coated surface treatment?

A: Anodized or powder-coated finishes provide an extra layer of protection against corrosion and wear, extending the lifespan of the grating. They also contribute to the products low maintenance requirements, keeping the surface looking clean and performing well over time.Q: How does this grating ensure fire safety and corrosion resistance?

A: Manufactured from high-grade aluminium, the grating is inherently non-combustible, meeting stringent fire safety standards. Its chemical composition and optional surface treatments provide excellent resistance to corrosion, even in aggressive industrial environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Fabricated Gratings Category

Steel Grating

Price Range 1500.00 - 15000.00 INR / Piece

Minimum Order Quantity : 200 Pieces

Product Type : Grating

Shape : Rectangle

Color : Black

Material : Steel

Fabricated Product

Price Range 1020.00 - 10200.00 INR / Piece

Minimum Order Quantity : 200 Pieces

Product Type : Grating

Shape : Rectangle

Color : Black

Material : Steel

Heavy Metal Grating

Price Range 1500.00 - 15000.00 INR / Piece

Minimum Order Quantity : 200 Pieces

Product Type : Grating

Shape : Rectangle

Color : Black

Material : Steel

Metal Grating

Price Range 1500.00 - 15000.00 INR / Piece

Minimum Order Quantity : 200 Pieces

Product Type : Grating

Shape : Rectangle

Color : Black

Material : Steel

|

BINAYAK HI TECH ENGINEERING LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry